Valves, seals, and an array of advanced components can be optimized with lapping machining! Our state-of-the-art lapping machines provide invaluable improvements for various utility applications, such as precise component development, tool repair, and like-new refinishing applications for worn or damaged parts.

All phases of your utility operations stand to benefit from a strategic lapping partner. Following the rough production of critical components, our strategic machining services can connect you with smoother finishes and unrivaled design accuracy. Before installing components, lapping machines’ finishing and shaping accuracy ensure component safety and equipment reliability.

Improve Equipment Performance

Whether you install conductive electrical components or require secure water-line valve performance, our precision lapping processes can fortify the fundamentals of your company’s infrastructure.

A single-part inaccuracy can lead to costly and catastrophic utility failures, and our quality-controlled polishing expertise is a simple step you can take to prevent equipment failures. Lapping machine surface shaping and finishing is appropriate for multiple materials, and can shield your bottom line from:

- Avoidable part replacements: Instead of replacing costly utility components worn or damaged, our lapping machines can restore many components to their original condition.

- Inconsistent equipment performance: Before your components are installed, utilize our experienced expertise and shield your operations with our proactive lapping expertise. Our skilled machinists can prevent a range of infrastructure issues caused by rough, uneven, or incorrectly-sized components.

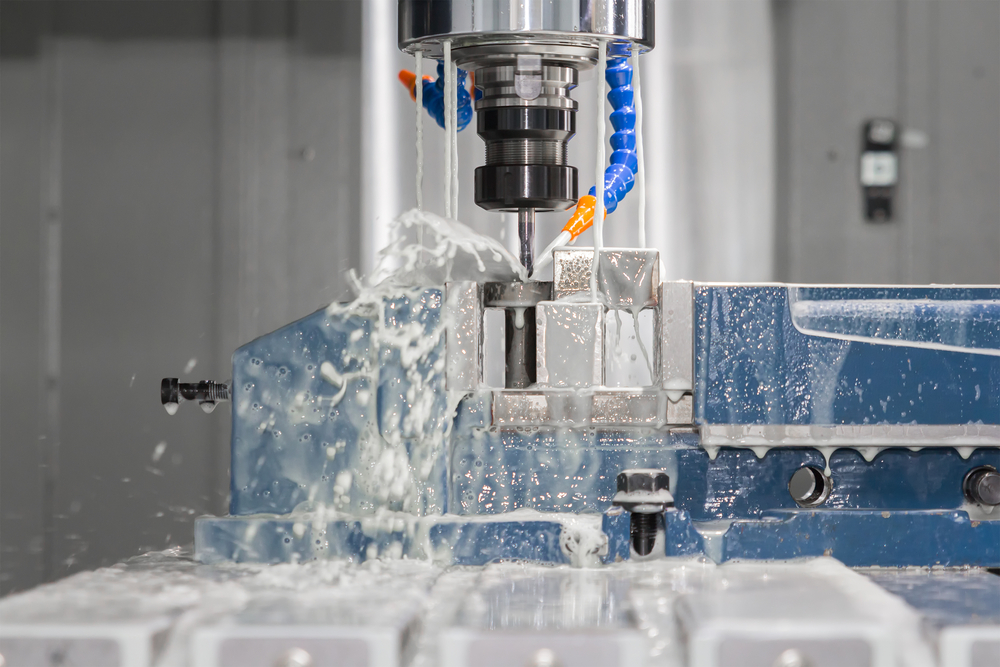

- Wasteful development processes: Our methodical polishing and finishing services prevent production waste with error-preventative CNC automation. If you have been searching for a cost-effective partner to design, refine, and repair your components with expedited consistency, count on our pros at Cer-Mac to support the foundation of your operations with aerospace-grade component accuracy.

Improve Customer Relations & Enhance Your Reputation

With our adaptive CNC machining services in Delaware County, PA uplifting the quality of your components, your utility business reaps the benefits for years to come. When properly-designed components support the fundamentals of your business, expect fewer service calls and fewer outages, and as a result, improve the overall experience for all water, electric, or gas clients.

Increase Staff & Customer Safety

Reliable part performance equals rising safety standards and fewer hazard-related litigation risks. Especially relevant if your team is regularly exposed to high-pressure gas and water systems or hazardous electrical installations, you cannot put a price on powering your team with expertly-designed components.

Your potentially-life saving investment in superior component quality also protects your customers. Serious hazards like gas leaks, electrical fires, and home flooding can all be prevented with better utility component design. And, avoiding an array of potential utility equipment consequences is as simple as joining forces with our experienced machining specialists!

With our organized and supportive CNC experts on the design, we take pride in providing defect-free development and impressive part turn-around times. For parts of any size, order volume, and design complexity, contact our helpful team at Cer-Mac for a free lapping machine estimate today.