ISO 9001:2015 Certified by ABS-QE

Cage Code: 53569 | Duns #: 061836920 | NACIS: 332710

Cer-Mac Inc. is a family-owned machining company with many years of service providing high-quality Swiss Screw machining and CNC Swiss turning for Warminster, PA and Bucks County, PA businesses. Custom Swiss Screw machining has become one of the most popular machining options throughout Pennsylvania for a reason: it produces fantastic results, reduces lead time dramatically, and improves part quality without costing a massive amount of money.

Before working with a Swiss Screw machining company like Cer-Mac Inc., it is important to understand what CNC Swiss Screw machining is and how it can benefit you. By understanding the CNC Swiss turning process and custom Swiss Screw machining processes, you can find the best machining options for your needs and budget for your next big manufacturing project without spending excess cash.

Custom Swiss Screw Machining is a high-quality production process that uses CNC Swiss Turning machines to create detailed, precise, and high-quality parts for Warminster, PA and Bucks County, PA firms. CNC Swiss Turning Machines use a computer-controlled setup that lets machining experts in Cer-Mac Inc. set the precise part size and shape that you need and control the cutting process properly.

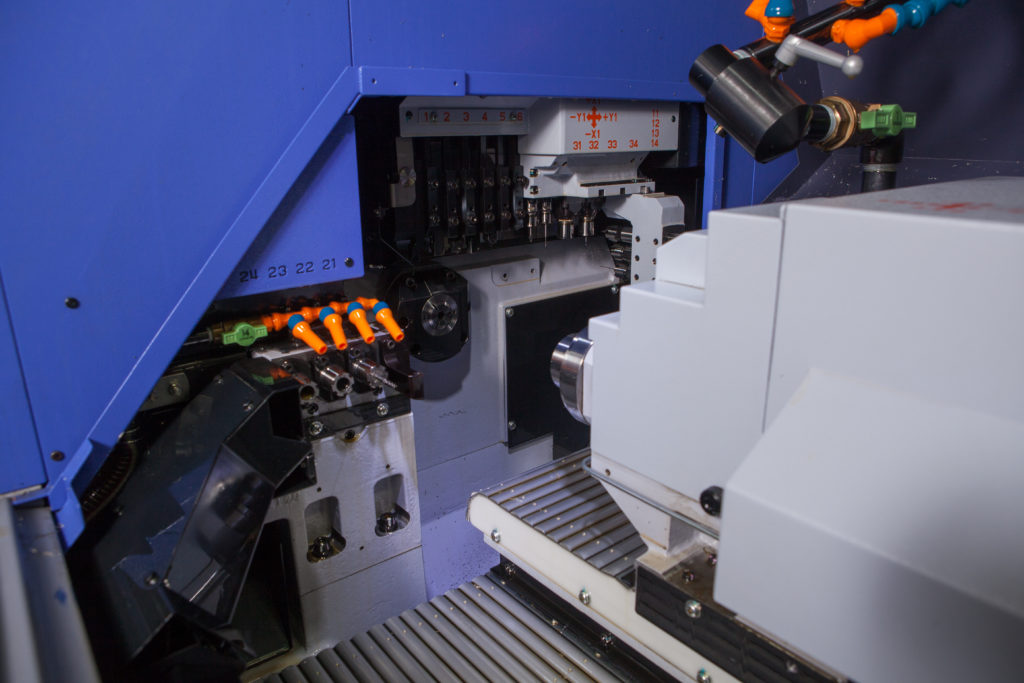

With our CNC Swiss Turning machines, we apply a cutting tool directly to your material at a high RPM with the part in rotational symmetry. Our machines can cut from between 0.15” to 0. 625 in diameter and up to 144” long. That’s good enough for just about any machining situation.

Request a Quote

We’ll be in contact with you soon.

As a CNC Swiss Machine shop, Cer-Mac Inc. has many years of experience producing high-quality parts. We’ve been open for over 50 years and continuously have adapted to the unique demands of the market many times over. Adding swiss turning to our shop was a major upgrade that helped us provide our customers with the highest-quality and most precise parts on the market today.

We specialize in live tooling and the whirling processes that CNC Swiss Screw machining provides. Each of our crew members is carefully trained to handle all your unique needs and will work hard to ensure that our process meets your needs. With our help, you can get the Swiss CNC turning services that you need for your parts.

At Cer-Mac Inc., our Swiss Turning machinists have unbelievable expertise. Swiss Turning provides your shop with the highest-quality parts at a more reasonable price. Even better, this machining process can provide many benefits that make it more than worth your investment, such as:

These benefits make our high-quality CNC Swiss Screw machining a powerful option for many people. As the leading CNC Swiss Screw machining company in Pennsylvania, we feel comfortable stating that we’ll fight for your needs and give you the high-quality parts that you want and deserve. It’s our commitment to you that makes us so successful with our many customers.

Swiss screw machining excels at producing small and complex components with impressive turnaround times. While it can take other CNC machines an hour to produce a single component, CNC Swiss turning can produce approximately 30 in that same time frame, depending on part size, complexity, and material type. How is this possible? In a typical Swiss turning setup, several tools engage with the workpiece simultaneously, allowing for multitasking operations without the need for a secondary finishing process.

Swiss Screw machining efficiency does not limit quality. These processes can achieve extremely tight tolerances with consistency. Due to machine rigidity, secure workpiece support, and narrow proximity between the cutting tools and the workpiece, reduced risk of tool deflection or material bending is the standard. The result is an excellent surface finish, reduced material waste, and the ability to produce highly intricate components quickly.

All of these CNC Swiss turning advantages complement its broad material compatibility. Swiss turning machines can shape metals such as stainless steel, aluminum, titanium, brass, and copper, in addition to plastics, composites, and certain ceramics to exact tolerances.

The achievable polished finish that is with lapping machining improves numerous aspects of part quality and equipment performance. Previously defective parts with rough edges and burrs can be transformed into truly smooth and effective parts. Uneven tapers or other dimensional inconsistencies can be safely recalibrated and optimized to enhance surface contact or reduce friction in mating or moving mechanisms. Whether utilized for part repairs or the finishing touches of an integral component, the versatile capabilities of lapping machining can add significant value to the fundamentals of your parts.

To ensure precise control over material removal rates, our advanced lapping machining processes are powered by sophisticated programming, professional-grade lapping slurry, and top-tier lapping machining equipment that can produce uniform parallelism of less than .00005-inch. This unparalleled surface finish promotes:

Swiss screw machining differs from traditional CNC turning processes in several ways. A key distinguishing feature is the sliding headstock and guide bushing that supports and guides the workpiece. This custom sliding and guiding feature, working in tandem with a collet to secure the workpiece, enhances cutting accuracy, tool accessibility, and reduces cutting vibrations.

Swiss screw machining’s multi-tool capacity also differs from other CNC turning models. Our machine shop can equip multiple tools to shape the workpiece such as drilling, milling, and turning tools, allowing for a range of complex part dimensions to be shaped in a single run.

CNC swiss turning, despite supporting a broad range of custom applications with enhanced efficiency, is not well-suited for large-diameter parts, short-length parts, and certain material types. CNC Swiss turning setups can also be time consuming and complicated. Organizing a production run often involves changing multiple tools and inputting a complex cutting program that can only be managed by a highly-qualified machinist.

Swiss screw machines are optimized for machining small to medium-sized parts that feature a high length-to-diameter ratio. When dealing with large-diameter workpieces, the rigidity and capacity of the machine can become limiting factors. Large-diameter parts also require heavier cutting forces, which can lead to increased vibration and reduced machining accuracy. In the case of short-length components, these parts may not fully utilize the capabilities of the sliding headstock and guide bushing, which are better suited for crafting long and slender components.

Furthermore, CNC Swiss turning is not always the best choice for heat-sensitive alloys and other brittle or hardened material types that require meticulous care to prevent deformation, tool wear, or cracking during the machining process. Since these material types require careful thermal regulation, specialty tool types, and advanced chip evacuation strategies, it may be more cost and time efficient to consider an alternative machine shop strategy.

However complex your part requests may be, optimizing your custom design is our machine shop’s specialty. Get in touch with our CNC experts and discover how our capable machinists can help you overcome production limitations with precision efficiency today.

© Copyright 2025 – Cer-Mac Inc: CNC Machining Specialists