ISO 9001:2015 Certified by ABS-QE

Cage Code: 53569 | Duns #: 061836920 | NACIS: 332710

RAM EDM machining is a unique and powerful machining option available at Cer-Mac Inc. Our team works hard to ensure that we give you only the best parts possible. Before considering RAM EDM for your manufacturing needs, it is important to understand exactly what these services are and how they can help you with your parts.

At Cer-Mac Inc., our team can provide sinker EDM machining services for businesses. This unique machining service enables manufacturers to expand their overall capabilities. We focus on quality over quantity and believe it is important to give you the best parts at the most economical price.

We carefully train our RAM EDM machinists. By fully licensing and certifying these professionals, we give them the ability to tackle the toughest tasks and ensure that quality remains high during each project.

Request a Quote

We’ll be in contact with you soon.

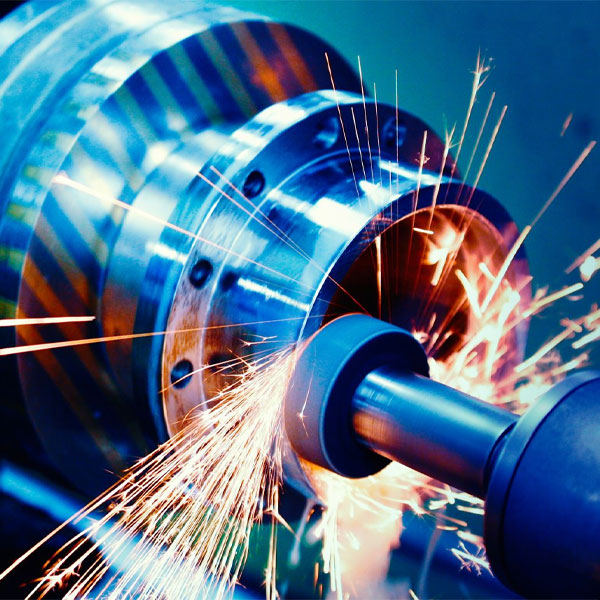

RAM EDM machining is a unique process designed to help with a variety of parts that require fine finishes and have thin walls. Cer-Mac Inc. also uses RAM EDM when working with parts that are difficult to hold and maintain after heat treatment. Sinker EDM machining uses several unique steps to create parts.

RAM EDM machining uses customized electrodes that create powerful sparks between the electrode and the material. Cer-Mac creates customized electrodes in-house to adhere to your needed RAM EDM specifications. It slowly and carefully removes materials to ensure that your intricate parts don’t break during the machining process.

RAM EDM capacities include a work tank that is 30.3 by 19.6 by 9.8 inches and a work table at 19.6 and 12.7 inches. Our maximum table load is 1,200 pounds. Regardless of the size, you will get a consistent, controlled burn you need to produce the high-quality parts that your shop needs.

Reasons to use sinker EDM machining over other options from our RAM EDM manufacturers include:

Our RAM EDM machinists work with a variety of materials when providing sinker EDM services for manufacturers. Material hardness does not affect this process, meaning that you can work with strong alloys, including:

These tough materials respond well to RAM EDM machining. Outside of specializing in machining difficult alloys, Cer-Mac also machines traditional metals, like stainless steel, titanium or aluminum. Let us know your needs and our team will work hard to help you!

Do you want to work with RAM EDM manufacturers that you can trust to handle your needs? Cer-Mac Inc. is the RAM EDM and wire EDM machining company for you! Call us at (215) 721-0120 to set up an appointment with our RAM EDM machining experts.

© Copyright 2023 – Cer-Mac Inc: CNC Machining Specialists