Few other devices demand the heightened level of precision as semiconductors do. Every component must coordinate harmoniously; from the properly-aligned resistors to the tightest of diode tolerances, a single poorly-designed component can render the entire device useless.

Any machine shop tasked with semiconductor machining must be able to manipulate a wide range of material types, employ a diversified team of specialists, and proactively adapt to the ever-evolving device requirements. Semiconductor components are becoming increasingly complex, and the team you source must be able to deliver the strictest of quality control standards and unrivaled production consistency.

More Than Mass Component Design & Production

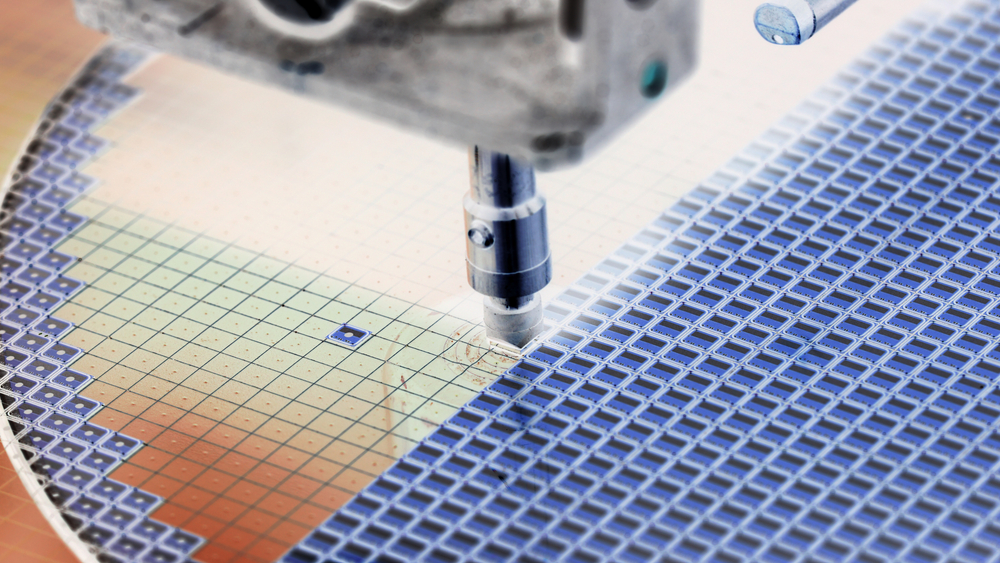

Alongside the machine shop’s relevant semiconductor CNC production capabilities, a working mastery of all conductive and insulating materials is essential. Since highly sensitive, ultra-thin semiconductor products are extremely fragile, appropriate machine selection and cautious material handling are just as important as the quality of the design.

To produce the smoothest of finishes and the tightest of tolerances for contracts in aerospace engineering and computing, every project managed by our material and machining specialists undergoes a multi-point development and inspection process. To ensure that precision guides every phase, our advanced machine shop powers every component with:

- More development opportunities: We unlock limitless component potential with advanced CNC machining equipment for complex shapes and sizes across the spectrum. From ultra-flat wafer designs to perfectly-cylindrical semiconductor components for flawless electronics of any kind, our well-equipped pros simplify the toughest of design challenges.

- Verified material quality: Our defect-free components begin and end with metals and materials that are exclusively sourced from trusted manufacturing partners. Our processes are further backed by multiple credentials and certifications ensuring the highest of industry standards.

- Guaranteed accuracy: With over 1,000 integrated CNC gauges and measurement tools in our arsenal, hyper-precision is the standard at Cer-Mac.

- Knowledgeable troubleshooting and support: We have experience with more component types, and can quickly help you optimize your component plans with an advanced team of engineers and manufacturing specialists ready to advise.

Access Scalable Component Production That Evolves With Your Needs

As your product line or development projects expand, are your machining specialists able to keep pace? As experienced CNC machinists, our unwavering goal remains the same for each project; connect our clients with the flexible guidance and consistent precision they need to build superior equipment and products.

With respect to your budget, timeline, and our guarantee of triple-checked accuracy, the best semiconductor designs are easily accessible at Cer-Mac. We can mass produce as many units as you will ever need while ensuring predictable material quality and dimensional consistency with every circuit, chip, or wafer chuck you need to be delivered on time.

Learn More About Our Machine Shop’s Versatile Capabilities Today

Before you purchase a single component, contact our specialists at Cer-Mac for a wealth of industry insight and product-specific education. We can quickly help you narrow down which production options are the most affordable, time-efficient, and precision aligned with your big-picture development goals.