Advances in precision machining have led to the emergence of life-saving devices, better implants, and highly sophisticated robotics that are minimizing the risks associated with human error. The world of healthcare is evolving rapidly, and our medical machining specialists are at the forefront of innovative component design – advanced machined components are now an integral necessity in all sectors of medicine.

When lives are on the line, there’s no room for faulty components or incorrect sizing. This is especially true in highly specialized designs such as pacemakers, joint implants, and other niche devices that directly contribute to human health. In addition to final product designs, many critical operating technologies now depend on flawless component precision. From surgical equipment sterilization processes to patient monitoring equipment, EDM precision can be found in every corner of the hospital or outpatient clinic.

Predictable & Repeatable Quality Comes With Optimized Machining

Medical industry needs are the perfect example of an industry that requires meticulous part consistency. In the operating room, surgeons, nurses, and anesthetists open their sterile packaging and rely on the exactness of their needles, intubation components, and surgical tools to perform as expected. The same need for part precision can be found in the radiology department, the oncology clinic, and the emergency room.

As a result, every parts and equipment manufacturer can benefit from development that complies with that level of precision and meets demanding product quotas. Supply issues are a common problem in many sectors of medicine, but by partnering with an ultra-proficient machining company in Bucks County, PA, it’s possible to scale production capabilities and improve final product quality simultaneously.

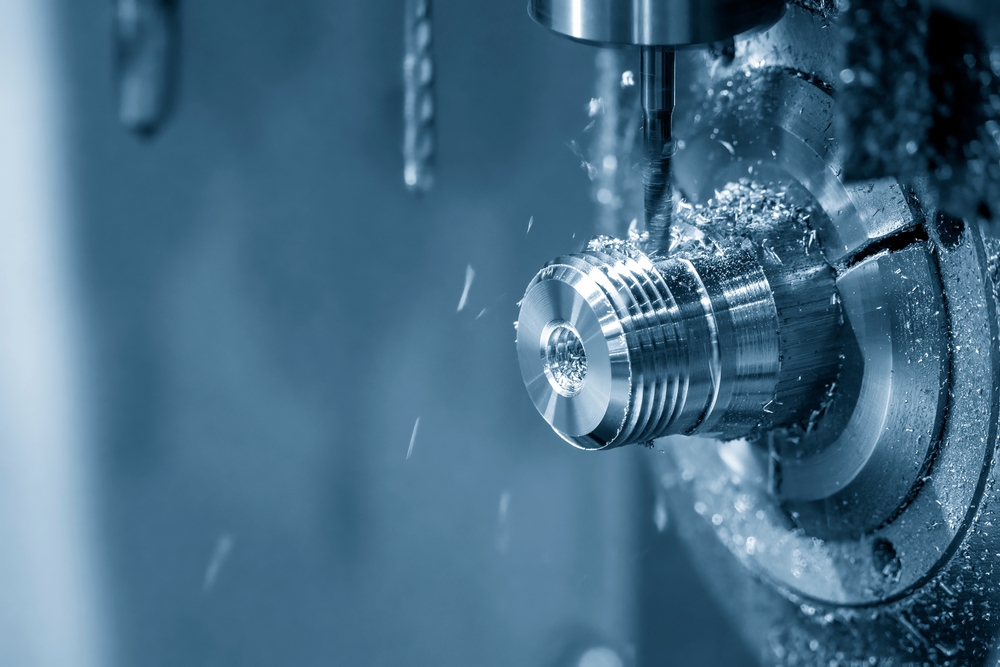

To achieve predictable development efficiency, we provide our clients with several versatile machining options. On the front end, our expert machinists can assist with every step of precision CNC development. With diverse support for everything from specialty robotic components to cost-efficient surgical tool design, our machining specialists are your all-in-one resource for faster production times and exceptional components that meet the strictest of standards.

Advanced Machining Drives Medical Equipment Evolution

Our facility can machine the hardest of materials like titanium and tungsten carbide with unrivaled accuracy. As a result, parts that were previously only available in aluminum or copper can now be formed from the toughest and non-magnetic materials in the industry. Think stronger medical tools, longer-lasting equipment, and reduced patient risk because their implants are now stronger than ever.

In addition to expanding upon available material options, the low-cost efficiency of CNC and EDM part design makes it easy to design and research invaluable prototypes for all sectors of medicine. Our ultra-fine capabilities can shape miniature geometries, extremely narrow keyholes, complex electrical components, and other impressive dimensions that were impossible to create with manual processes.

Modern Machining is Reshaping Savings & Environmental Preservation

Arguably as important as final product quality, the benefits of our precision machined parts cut costs and reduce the environmental impact of component production. With efficient processes such as wire Electrical Discharge Machining, material waste is reduced and production errors are minimized. By making the switch to lean and streamlined processes such as this, your bottom line is shielded from costly reruns, disposal fees, and even the potential for compliance fines if your production processes pose an environmental hazard.

Our machine shop also makes it easy to outsource all stages of advanced part integration. Instead of managing independent production, our cost-effective expertise can help you achieve consistent component quality for less. Contact our pros at Cer-Mac and learn how we can improve your parts, reduce your costs, and deliver flawless components sooner than expected.