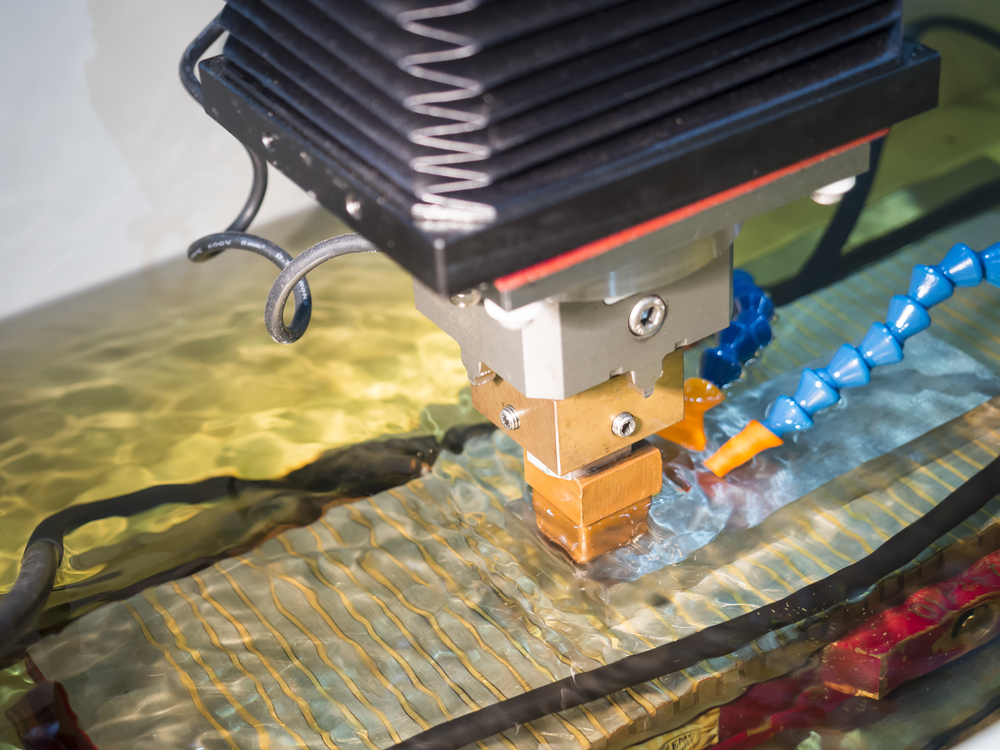

Optimize operational flow from the base components to the finished stages with EDM precision. Thanks to the versatility of Electrical Discharge Machining, our specialty machine shop in Montgomery County, PA can create incredibly complex and precise components without compromising on cost, efficiency, or design. Serving diverse industries, from energy extraction to the semiconductor industry and more, here’s why EDM precision may be the solution your company needs.

Reduce Production Waste With EDM Accuracy

Predictable component design is the standard in EDM development. If your production processes rely on crude machining methods, minor defects and differences in components can undermine the safe functionality or quality of your final products. Since the EDM process utilizes electrical discharges to erode the workpiece instead of physical force, the result is:

- Tighter tolerances that align with blueprint specifications

- The ability to produce highly intricate component types

- Repeatability for enhanced production accuracy and efficiency

- Reduced material waste and production costs: Traditional machining methods require frequent part replacement due to excess wear and tear; EDM methods prevent common production problems like breakage and tool damage

Improve Final Product Quality With Better Base Components

Since EDM makes it easy to modify components from many metal types, EDM precision can complement the fundamentals of the products and equipment your business relies on. Capable of cutting and shaping brass, alloys, titanium, steel, and other conductive metals, supporting your product line with superior parts can now be accomplished for less.

Our lean RAM EDM machining is also a cost-effective solution for damaged component repair and refinishing processes. For instance, if your shop produces a line of aftermarket automotive parts, you can ship the parts to our experts to etch logos, and smooth surfaces, or clean up any defects with machining accuracy that is guaranteed to impress any clients who receive the expertly-finished parts.

Increase Your Productive Output With Scalable EDM

As important as predictable precision, our partners gain a competitive edge with our comprehensive support expediting their part development needs. Our advanced EDM services can provide a scalable supply of parts on-demand, making our well-equipped shop the go-to source to meet your current and growing production expectations. Our experienced and extremely knowledgeable machining specialists evaluate each design with caution, ensuring that all production processes reduce material costs and maximize effective output.

In addition to streamlining part production, our organized processes make it easier to source and create new parts. For large parts, miniature defect repairs, and many other adaptive machining services, our full-service shop is your one-stop shop whenever you need to develop a revolutionary part from square one.

Our Precision EDM Processes Enhance Your Company’s Capabilities

We hold our team to the highest industry standards, and only ship parts if they meet our strictest standards of consistency and precision. To learn more about our versatile machining capabilities, contact our machinists for products your company can be proud of.