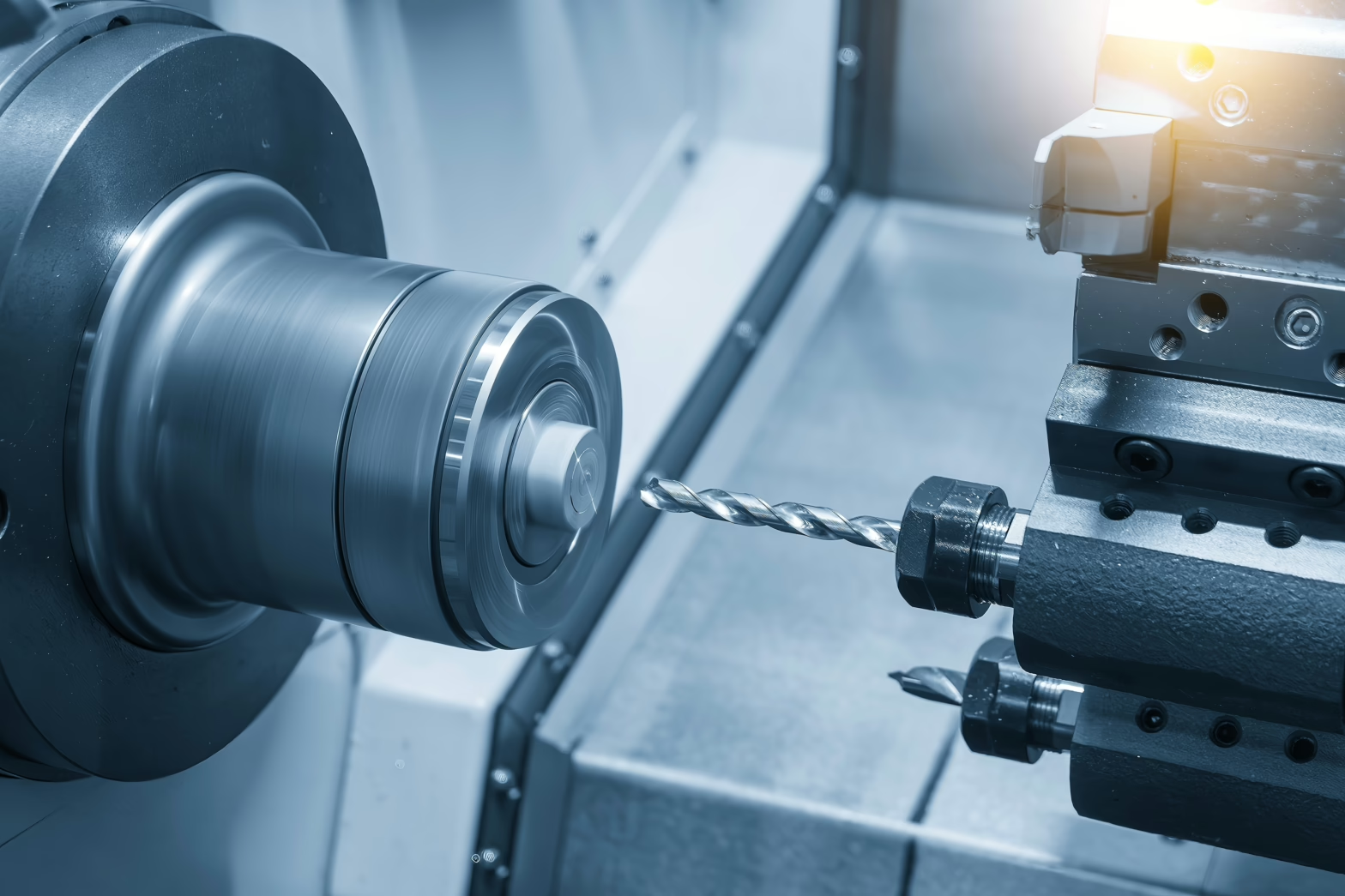

Have you ever wondered why some parts fail under pressure while others seem to defy the harshest conditions? In oil and gas operations, the difference often comes down to the precision, expertise, and processes behind the part. When your precision machined parts are exposed to extreme temperatures, high pressures, and corrosive elements, every component must… Continue reading Custom Machined Metal Parts for Oil and Gas: What Makes a Component Truly Unbreakable?

Custom Machined Metal Parts for Oil and Gas: What Makes a Component Truly Unbreakable?