ISO 9001:2015 Certified by ABS-QE

Cage Code: 53569 | Duns #: 061836920 | NACIS: 332710

For the utmost precision, many machinists turn to CNC turning and CNC Swiss turning. The option you choose will depend on the level of detail you need in your parts. Both offer excellent benefits and many features. We are going to explore what each can do for you.

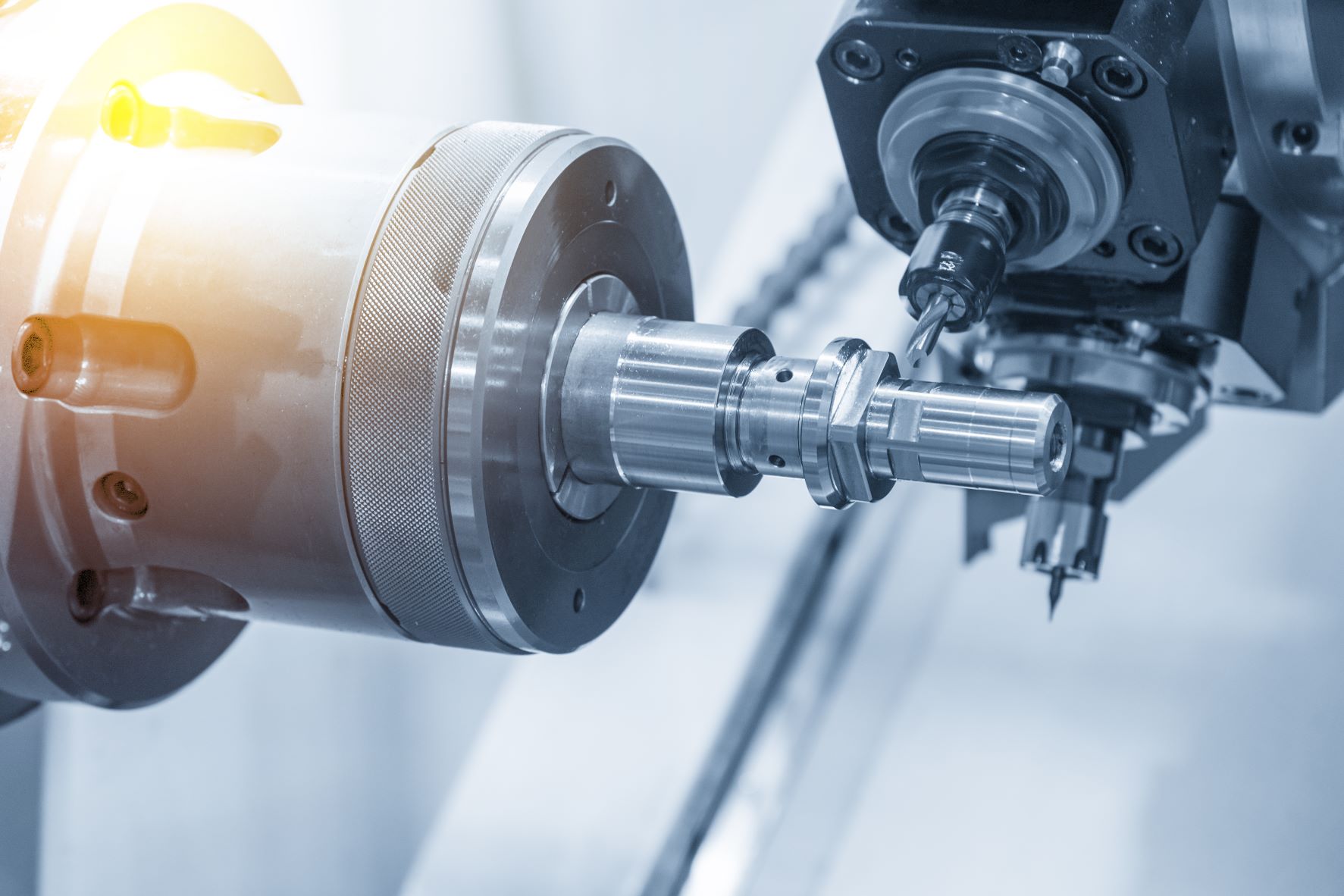

CNC turning is a removal technique to take material from an original bar of material until the desired shape is achieved. The original material is held securely in a chuck rotated as a removal tool takes the excess material off.

CNC turning machines offer all of the following services:

Special features are also available when the CNC turning services offered use Live Tooling machines. These machines can pause rotation for the addition of things like milled surfaces and drilled holes.

CNC Swiss Turning machines are used for the creation of the smallest parts. These machines are notable for their quick and accurate work. Like CNC turning, the machined bar is firmly held and fed into the machining area.

This process differs significantly from CNC turning because the material bar is not restricted to rotating in one fixed position. For CNC Swiss turning, the option exists to move the material along the Z-axis as needed to create even more features.

Additionally, CNC Swiss turning is not limited to performing one task at a time. It is often used to perform several operations simultaneously. These operations are also not restricted to one zone, as this machine can operate in multiple zones simultaneously.

When you need precision CNC turning services or CNC Swiss turning services, don’t hesitate to reach out to Cer-Mac Inc. Our commitment to defect-free parts and on-time delivery will make you glad you did! Call us at (215) 721-0120 today.

© Copyright 2023 – Cer-Mac Inc: CNC Machining Specialists