ISO 9001:2015 Certified by ABS-QE

Cage Code: 53569 | Duns #: 061836920 | NACIS: 332710

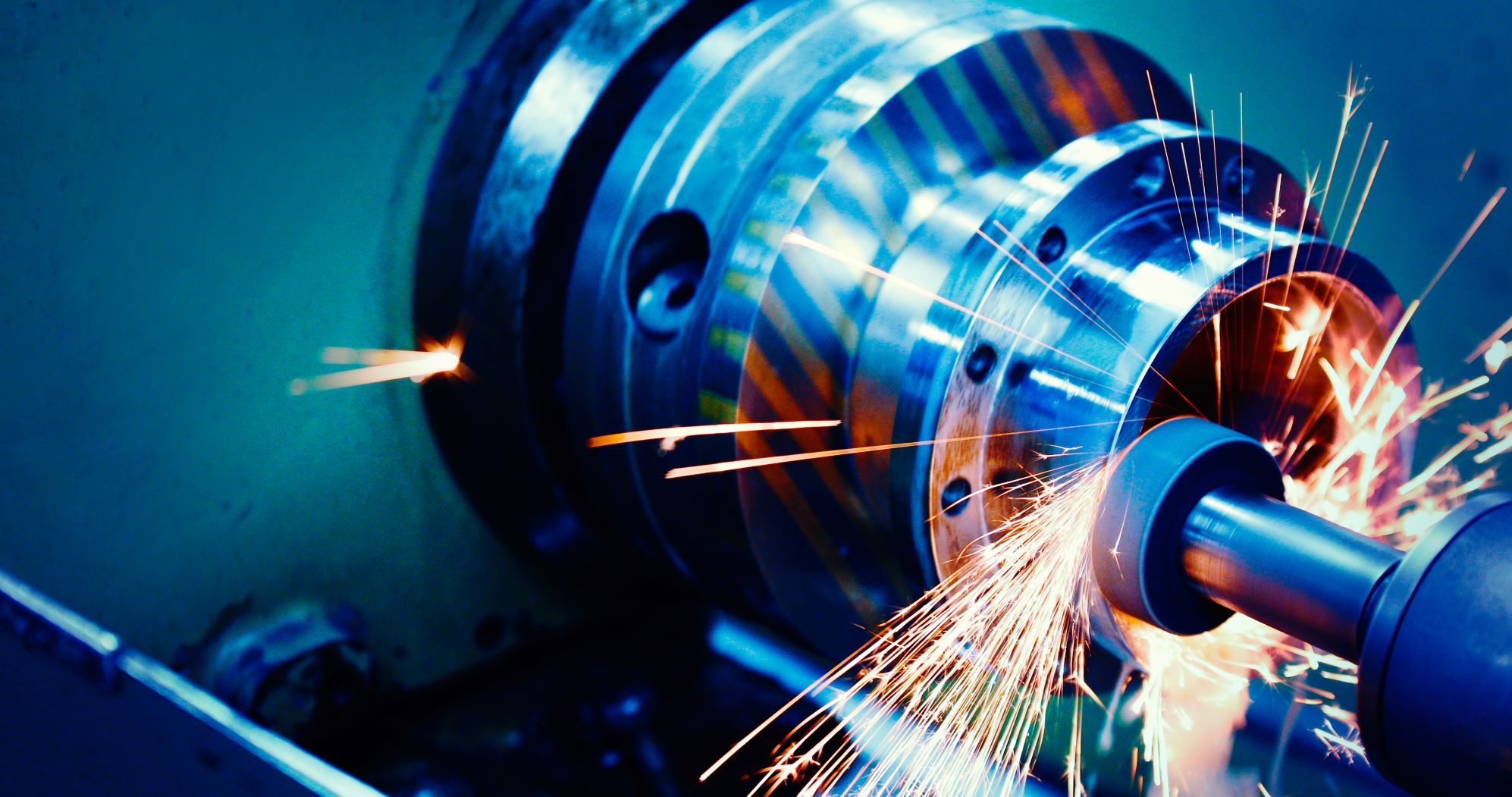

Details matter when dealing with government defense contracts. From the integrity of the raw materials used, to the affordability and capabilities of the shops, there’s no room for error when it comes to quality-controlled CNC machining. Since critical machined parts are involved in final applications like military defense equipment, medical research, and other priority applications like space technology, national defense companies go to great lengths to ensure that the components they receive are of the highest caliber.

Like every product on the market, precise machine components are not immune to knock-offs and adulterations. In the world of machined components, an adulterated component can result in life-threatening and/or extremely expensive failures in the field. To diminish these potential risk factors, a CNC machine shop must acquire and maintain several certifications before bidding on any Department of Defense contracts. These certifications ensure that the shop complies with legal material sourcing, operates with secure practices, and its production processes meet strict standards for product quality and accuracy.

To ensure a higher standard of product quality and precision accuracy, our CNC machining services in Delaware County, PA maintain:

Along with the direct safety benefits and equipment assurances that come with compliant component manufacturing, these credentials establish a foundation of trust for potential partners. By demonstrating the ability to produce top-tier components for complex projects like high-value aerospace or defense equipment, any company that needs reliable parts can comfortably assume that our shop will be able to exceed their expectations.

Since earning and maintaining these credentials can only be achieved with a professional balance of advanced equipment and experienced 5-axis machining specialists, it’s also more likely that a credentialed shop will be able to adapt without delay. For example, if you need an ultra-precise and complex component that is likely beyond the expertise of your local machine shop, our machine shop actively fulfills complex defense contracts and has a working mastery of the equipment and materials required for virtually any job.

Along with the guaranteed quality of production, the scalable capabilities of a machine shop are equally important. At Cer-Mac, our organized processes result in shorter lead times for the crucial components you need, with every priority component designed and produced with the latest advancements in machining. With our clear communication and a greater range of beneficial CNC applications, we gain an edge in production and customer satisfaction with the precise and affordable components you need to be delivered directly to you.

© Copyright 2025 – Cer-Mac Inc: CNC Machining Specialists