Our end users require Cer-Mac to produce the most precise machined parts with intricate ID features. Components for the oil and aerospace industries require long shafts with several ID features that have tolerances within the thousandth of an inch. Precision machining has become the norm for these industries.

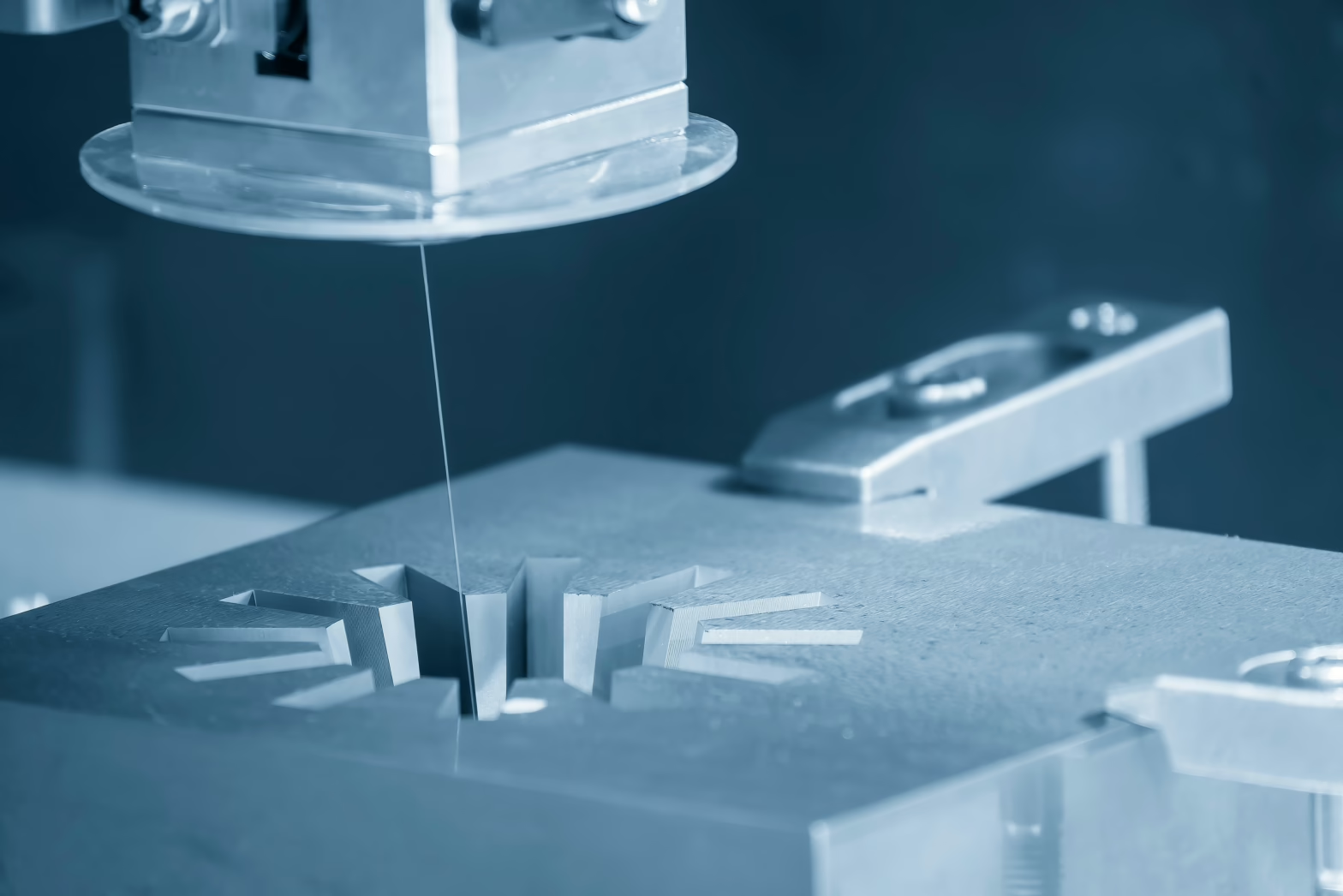

Key features like deep downhole hexes and keyways are now achievable with the advent of new technology. Our RAM and wire EDM departments are able to machine precision hexes down the ID of our parts. This specific part required a .813″ hex 2″ into the part. The incredible tricky aspect for this operation was that we could not impact the threading on the other side of the hex. Achieving those dimensional requirements would have been near impossible on a “regular” milling or lathe machine.

After internal review, our production team decided that WIRE EDM’ing this dimension was the safest and most time-efficient way to achieve this hex. A complex design component which would’ve taken numerous hours on a mill with a risk of fall out was quickly programmed, machined, and sent to inspection within a day.

Wire and RAM EDM has changed the dynamic of our production floor. We are able to easily machine hexes, keyways, and other internal features with ease and precision. Cer-Mac has 4 Mitsubishi wire EDM machines and 1 Mitsubishi RAM machine. There is plenty of open capacity in both departments.

What can we machine for you?

Call me today, let’s talk!

215-721-0120