CNC machining is known for its repeatability when producing parts that meet exact tolerances and design specs. It’s ideal for use in a variety of industries, especially in the robotics industry. CNC machining experts take in the client’s blueprints and specs, then translate the information into a program that the CNC machines follow without deviation. The end result is a precision machined part that’s finished in less time than traditional machining methods, and fits perfectly the first time it’s installed. Here’s a look at what a machining company can achieve for the robotics industry.

How CNC Machine Shops Produce Precision Parts for Robotics

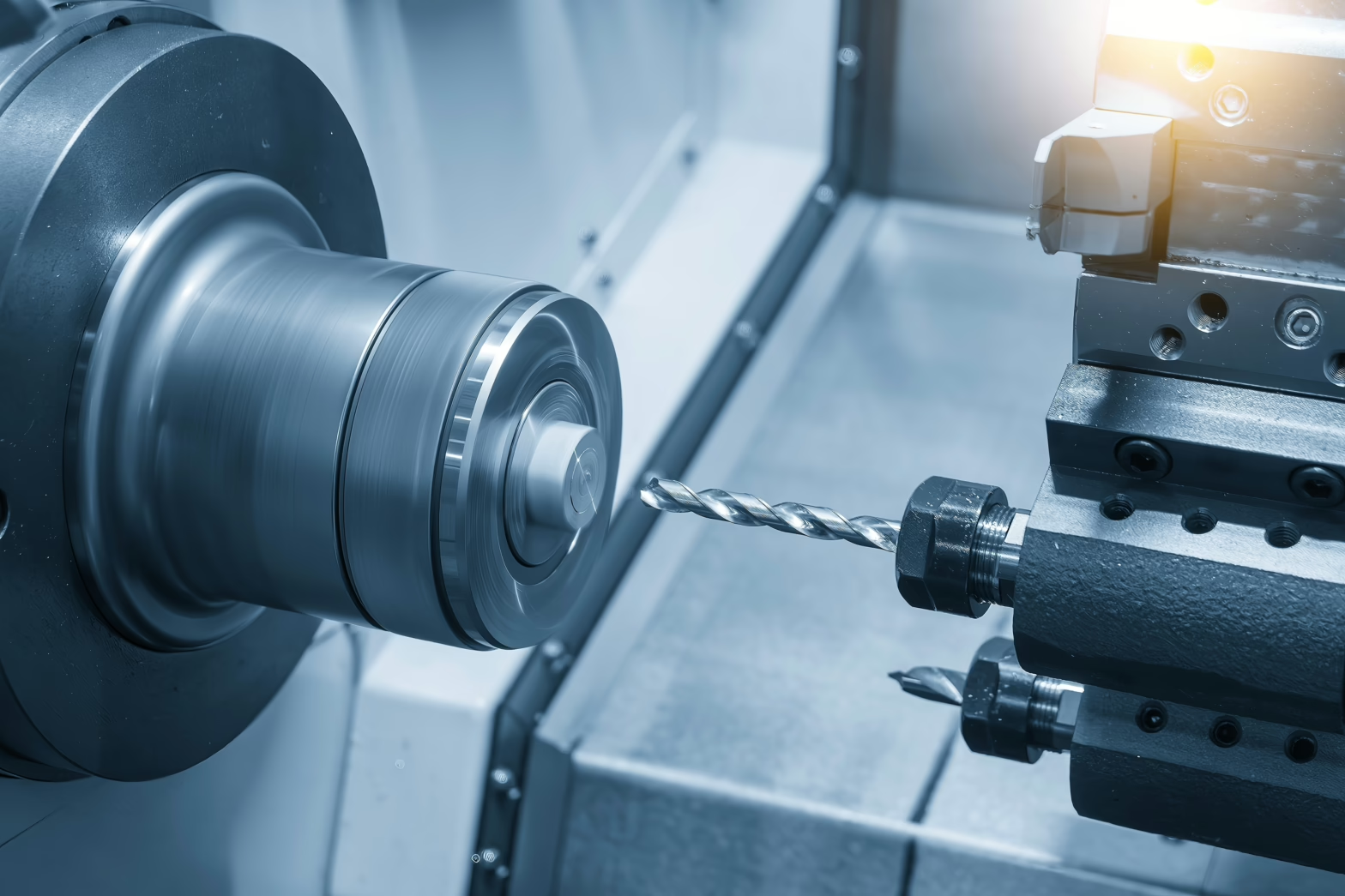

Specialists use the latest in CNC technology and software to make parts that come out correctly on the first run. Provided the drawings and tolerances are correct, a 5-axis CNC milling machine can produce a part the moment the operator presses the run button. Once the machine has completed its work, the part is checked for correct tolerances, and examined for defects.

After completing the inspection process, , the part is sent for protective coating, and then shipped to the customer. A machining company can turn around a part for custom aerospace machining in a short amount of time, with the customer being able to engage in their production process with minimal lag time. .

CNC Machine Shops are Capable of Machining Parts in All Dimensions

CNC machines have the ability to create parts in multiple dimensions to meet customer specifications. A machining company can take a round bar bar or square block and turn it into a part that’s identical to the original blueprint. The finished part holds the details perfectly, and is ready to go into use the moment it arrives.

Customers can get the parts they need through the use of CNC turning machining, milling, wire cutting, and more. CNC machine shops use a variety of CNC machines for the purpose of creating finely crafted parts for the robotics industry. Skilled specialists at CNC machine shops ensure accuracy by reviewing designs before machining, monitoring the process for efficiency, inspecting dimensional tolerances during production, and conducting a final inspection to verify specifications.”

Producing Parts to Customer’s Specifications

The robotics industry is one that requires unique parts that are precision machined. Robots make repetitive movements that need to follow the same path of motion every time they perform a cycle. Some robots can perform these repetitive cycles hundreds, if not thousands, of times an hour. The cycles put strain on the part, underscoring the need for a part that was made correctly the first time around. Experts recognize this core requirement, and make it a point to deliver a part that matches the blueprint.

CNC machine shops understand that their customers need a part that performs correctly. They work closely with their clients to make sure that the original blueprint is correct, use the right raw material, and that it is finished to the correct hardness.

How CNC Machine Shops Reduce Waste

One aspect of machining incredibly precise parts is the constant possibility of errors, which can lead to material waste.Utilizing the services of a machine shop in Willow Grove, PA, that has decades of experience in CNC machining is the best way to reduce waste. The experts at Cer-Mac Inc. have the knowledge that’s needed to get the part done right the first time, and the ability to reduce waste.

Get Your Robotics Parts Done Right the First Time

Cer-Mac’s CNC Machining Specialists have over 50 years of experience producing parts for a wide range of industries. We take our customers’ blueprints and specifications, and turn them into finished parts that fit and perform right from the moment they’re installed. Give us a call today to learn more about our services, and how we make parts that meet and exceed your expectations.