ISO 9001:2015 Certified by ABS-QE

Cage Code: 53569 | Duns #: 061836920 | NACIS: 332710

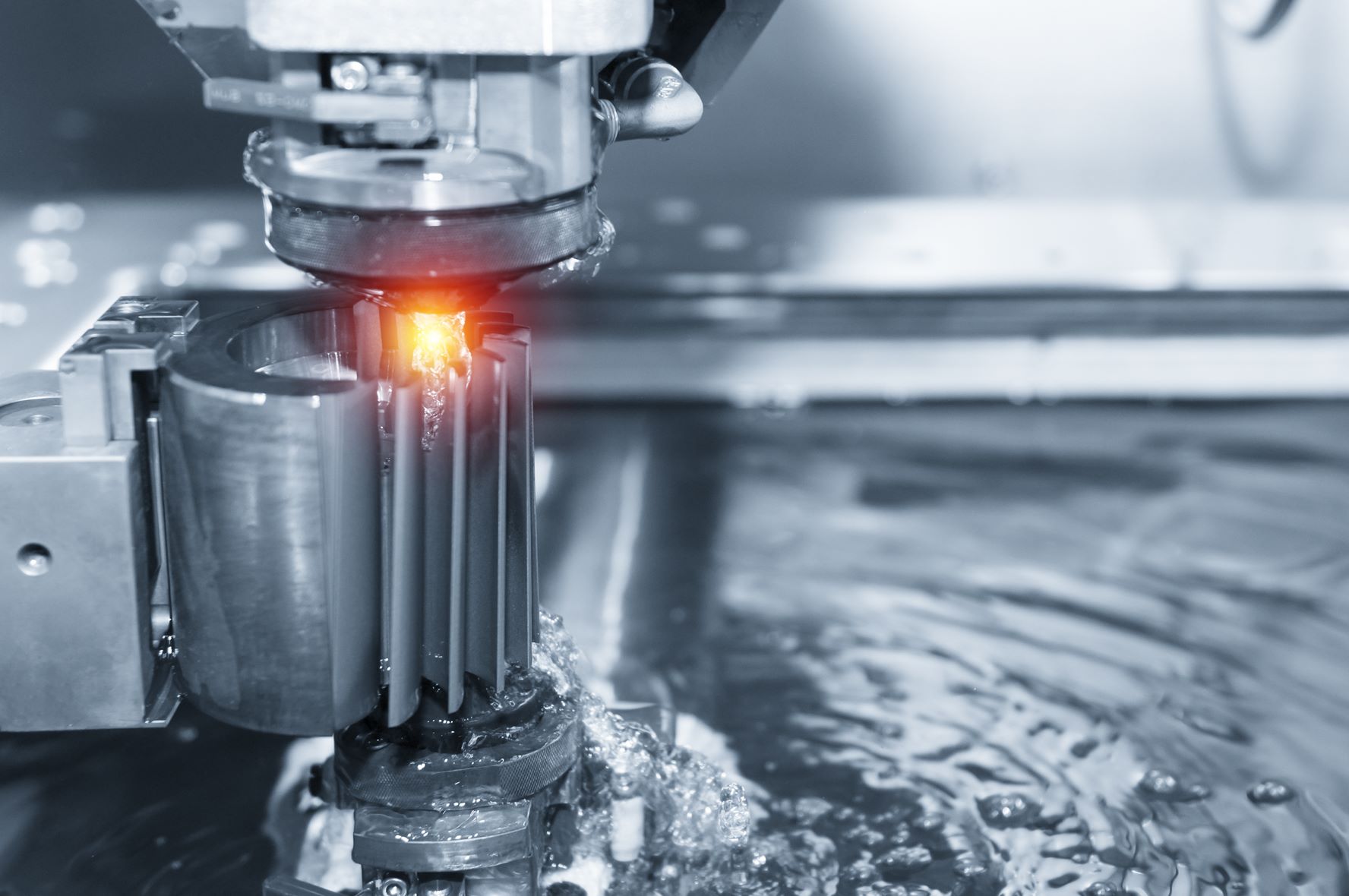

When the precision details matter, the versatility of Ram EDM (Electrical Discharge Machining) opens the door to hyper-accurate component design. Also known as spark machining or spark erosion, this incredibly accurate process uses the power of electrical discharges to shape metal parts. Unlike conventional drilling or milling processes, Ram EDM is ideal for manufacturing hardware when complex shapes, thin walls, and an ultra-smooth finish is the only acceptable standard. Here are 5 things to know about this process.

Compatible with a range of material types, our seasoned Ram EDM manufacturers can produce an array of flawlessly-designed parts, such as:

With tolerances of +- 0.00015 inches and no burn marks left behind, expect a smooth and defect-free finish with every EDM production run. Our Ram EDM processes are not affected by material hardness, meaning that you can work with strong materials like steel, tungsten carbide, cobalt alloys, and an array of other traditional and ultra-dense metals alike.

Thanks to the diverse capabilities of Ram EDM, complex parts can be produced quickly and repeatedly. Our EDM equipment utilizes CNC (computer numerical control) inputs for ease of streamlined consistency, allowing our skilled operators to save component profiles and replicate component development for specific and defect-free parts in less time.

Since the precision of EDM is quality controlled from start to finish, there are fewer production errors. Unlike conventional drilling and machining processes, EDM processes do not utilize physical force to shape objects, meaning issues like warping and cracking are eliminated from the equation. This can result in significantly reduced production expenses while simultaneously improving component durability.

In tune with the spectrum of adaptable material types, our streamlined processes allow for flexible revision adjustments. We can quickly source another metal type using the same component profile, or we can help you recalibrate a design with minor adjustments to improve your product performance or durability.

With so many different machining options available, finding the right process to produce the parts you need is often the most complicated step. When you get in touch with our seasoned machine specialists at Cer-Mac, we’ll help you navigate:

For more information about the many ways our Ram EDM processes can streamline your efforts, contact our precision experts at Cer-Mac for guidance today.

© Copyright 2023 – Cer-Mac Inc: CNC Machining Specialists